The World Health Organization declared Novel Coronavirus (COVID-19) a pandemic that is rapidly spreading across the globe. The global count by the time of writing stood at over 1.2 Million COVID-19 confirmed cases, with Fifty-Two (52) in Uganda. Critical COVID-19 cases once hospitalized and placed in the Intensive Care Unit for management require a respiratory assistive technology known as a Ventilator.

Analysts have projected increased global demand for ventilators resultant from the continual increase in severe COVID-19 cases. An increase in conventional ventilator production is very likely to fall short of global demand and with high associated cost. In the United States alone, the COVID-19 pandemic has been projected to result into ventilator shortages in the order of 300,000-700,000 units. Uganda has 12 functional Intensive Care Units equipped with a total of 55 functional beds implying an estimated 55 ventilators; in other words, 1.3 beds (with ventilators) per a million people. The ventilators on the market are prohibitively expensive (Price of USD 25,000 per ventilator) for low income countries like Uganda. There is therefore need for low cost ventilators that can be manufactured locally. Such ventilators would bolster the country’s surge capacity to provide critical care in case the demand for such care increases.

Makerere University, ResilientAfrica Network (RAN) a project of the School of Public Health, Kiira Motors Corporation, Ministry of Science, Technology and Innovation (MOSTI) have thus scanned the COVID-19 Healthcare Frontline with the view of exploring the Science, Technology, Engineering and Innovation contribution to the solution space in averting the pandemic in Uganda. These parties are therefore working round the clock toward the development of an Open Design Low-Cost Ventilator adapting open access designs from the Massachusetts Institute of Technology, University of Florida, and other Public License Ventilator Technology Developers, to the needs in Africa placing strategic emphasis on Supply Chain Localization to engender the scaling of production. The capacity developed in the area for local content participation in the manufacture of Low-Cost ventilators will be valuable to Uganda even beyond the COVID-19 Pandemic.

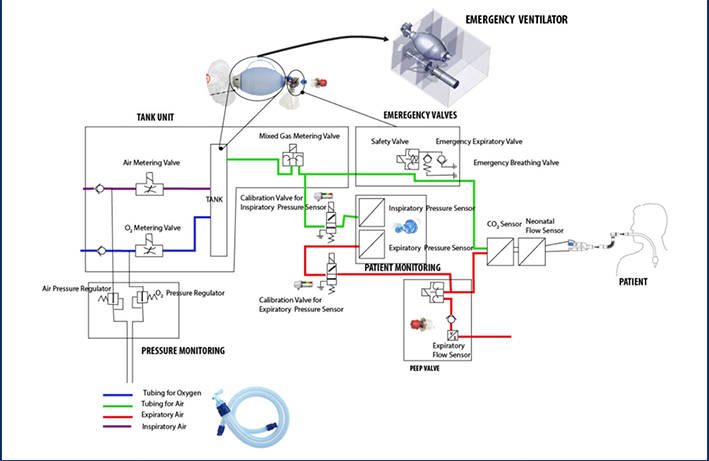

The proposed Ventilator is based on an electromechanical Architecture utilizing Motors, Potentiometers, Air Pressure Transducers, Air Flow Transducers, a Valve Mask Compression Unit, Inhalation & Exhalation Control Valves, and a Monitoring System. These assist in inhalation and exhalation by increasing and decreasing the patient’s airway pressure or tidal volume through controlled inhalation and exhalation.

The Ventilator Architecture, Operational Mechanism and underlying technology are similar to Vehicular Powertrain Systems from a Technology Perspective. Perhaps that is why it is not surprising to see several global automotive manufacturers such as General Motors, Mercedes Benz, Tesla, and Ferrari among others, have been able to switch Vehicle Plants to manufacturing of Ventilators in some cases using parts of their Vehicle Model Supply Chain.

This pioneering collaborative effort in Uganda is in consonance with Makerere University’s School of Public Health commitment to train skilled public health professionals who can develop innovative methods to address public health challenges in the communities. It draws on the wealth of expertise and experience professionals have applied in other critical healthcare domains such as management of Ebola, as well as the resultant development of the patented EpiTent to prospect a positive result in this initiative.

The capacity Kiira Motors Corporation has developed in Electric Vehicle Systems Development position this collaborative effort as a timely intervention leveraging National Resource available at established Facilities at Luweero Industries Limited, Uganda Industrial Research Institute, among others, to engender the manufacturing of key components and support the short to medium term production needs.

The Ministry of Science, Technology and Innovation will work closely with the Ministry of Health, Uganda National Bureau of Standards and other Key Stakeholders to provide policy guidance and coordination to ensure the project results meet National and International Standards for Technology of such a nature.